Studies show that the ratio of indirect costs to direct costs varies widely, from a high of 20:1 to a low of 1:1. OSHA has shown that the lower the direct costs of an accident, the higher the ratio of indirect to direct costs (ranging from 4.1/1.0 to 1.1/1.0). Examples of indirect costs include training replacement employees, accident investigation and implementation of corrective measures, lost productivity, repairs of damaged equipment and property, and costs associated with lower employee morale and absenteeism.

Studies show that the ratio of indirect costs to direct costs varies widely, from a high of 20:1 to a low of 1:1. OSHA has shown that the lower the direct costs of an accident, the higher the ratio of indirect to direct costs (ranging from 4.1/1.0 to 1.1/1.0). Examples of indirect costs include training replacement employees, accident investigation and implementation of corrective measures, lost productivity, repairs of damaged equipment and property, and costs associated with lower employee morale and absenteeism.

Tag: safety

Electrical Safety

Electrical current exposes workers to a serious, widespread occupational hazard; practically all members of the workforce are exposed to electrical energy during the performance of their daily duties, and electrocutions occur to workers in various job categories. Many workers are unaware of the potential electrical hazards present in their work environment, which makes them more vulnerable to the danger of electrocution.

Electrical current exposes workers to a serious, widespread occupational hazard; practically all members of the workforce are exposed to electrical energy during the performance of their daily duties, and electrocutions occur to workers in various job categories. Many workers are unaware of the potential electrical hazards present in their work environment, which makes them more vulnerable to the danger of electrocution.

via CDC – Electrical Safety – NIOSH Workplace Safety and Health Topic.

What are the major changes to the Hazard Communication Standard?

The three major areas of change are in hazard classification, labels, and safety data sheets.

The three major areas of change are in hazard classification, labels, and safety data sheets.

- Hazard classification: The definitions of hazard have been changed to provide specific criteria for classification of health and physical hazards, as well as classification of mixtures. These specific criteria will help to ensure that evaluations of hazardous effects are consistent across manufacturers, and that labels and safety data sheets are more accurate as a result.

- Labels: Chemical manufacturers and importers will be required to provide a label that includes a harmonized signal word, pictogram, and hazard statement for each hazard class and category. Precautionary statements must also be provided.

- Safety Data Sheets: Will now have a specified 16-section format.

The GHS does not include harmonized training provisions, but recognizes that training is essential to an effective hazard communication approach. The revised Hazard Communication Standard (HCS) requires that workers be re- trained within two years of the publication of the final rule to facilitate recognition and understanding of the new labels and safety data sheets.

via Hazard Communication.

Motor Vehicle Safety

![]() Motor vehicle-related incidents are consistently the leading cause of work-related fatalities in the United States. Thirty-six percent of occupational fatalities reported by the Bureau of Labor Statistics are associated with motor vehicles. Between 2003-2010, on average:

Motor vehicle-related incidents are consistently the leading cause of work-related fatalities in the United States. Thirty-six percent of occupational fatalities reported by the Bureau of Labor Statistics are associated with motor vehicles. Between 2003-2010, on average:

- 1,275 workers died each year from crashes on public highways

- 311 workers died each year in crashes that occurred off the highway or on industrial premises.

- 338 pedestrian workers died each year as a result of being struck by a motor vehicle.

Source: U.S. Department of Labor, Bureau of Labor Statistics

via CDC – Motor Vehicle Safety – NIOSH Workplace Safety and Health Topic.

Prevention of Musculoskeletal Disorders in the Workplace

Musculoskeletal disorders (MSDs) affect the muscles, nerves and tendons. Work related MSDs (including those of the neck, upper extremities and low back) are one of the leading causes of lost workday injury and illness. Workers in many different industries and occupations can be exposed to risk factors at work, such as lifting heavy items, bending, reaching overhead, pushing and pulling heavy loads, working in awkward body postures and performing the same or similar tasks repetitively. Exposure to these known risk factors for MSDs increases a worker’s risk of injury.

Musculoskeletal disorders (MSDs) affect the muscles, nerves and tendons. Work related MSDs (including those of the neck, upper extremities and low back) are one of the leading causes of lost workday injury and illness. Workers in many different industries and occupations can be exposed to risk factors at work, such as lifting heavy items, bending, reaching overhead, pushing and pulling heavy loads, working in awkward body postures and performing the same or similar tasks repetitively. Exposure to these known risk factors for MSDs increases a worker’s risk of injury.

But work-related MSDs can be prevented. Ergonomics — fitting a job to a person — helps lessen muscle fatigue, increases productivity and reduces the number and severity of work-related MSDs.

What Can Be Done to Control Hazardous Energy?

Failure to control hazardous energy accounts for nearly 10 percent of the serious accidents in many industries. Proper lockout/tagout (LOTO) practices and procedures safeguard workers from the release of hazardous energy. The OSHA standard for The Control of Hazardous Energy (Lockout/Tagout) (29 CFR 1910.147) for general industry outlines measures for controlling different types of hazardous energy. The LOTO standard establishes the employer’s responsibility to protect workers from hazardous energy. Employers are also required to train each worker to ensure that they know, understand, and are able to follow the applicable provisions of the hazardous energy control procedures:

Failure to control hazardous energy accounts for nearly 10 percent of the serious accidents in many industries. Proper lockout/tagout (LOTO) practices and procedures safeguard workers from the release of hazardous energy. The OSHA standard for The Control of Hazardous Energy (Lockout/Tagout) (29 CFR 1910.147) for general industry outlines measures for controlling different types of hazardous energy. The LOTO standard establishes the employer’s responsibility to protect workers from hazardous energy. Employers are also required to train each worker to ensure that they know, understand, and are able to follow the applicable provisions of the hazardous energy control procedures:

- Proper lockout/tagout (LOTO) practices and procedures safeguard workers from the release of hazardous energy. The OSHA standard for The Control of Hazardous Energy (Lockout/Tagout) (29 CFR 1910.147) for general industry, outlines specific action and procedures for addressing and controlling hazardous energy during servicing and maintenance of machines and equipment. Employers are also required to train each worker to ensure that they know, understand, and are able to follow the applicable provisions of the hazardous energy control procedures. Workers must be trained in the purpose and function of the energy control program and have the knowledge and skills required for the safe application, usage and removal of the energy control devices.

- All employees who work in the area where the energy control procedure(s) are utilized need to be instructed in the purpose and use of the energy control procedure(s) and about the prohibition against attempting to restart or reenergize machines or equipment that is locked or tagged out.

- All employees who are authorized to lockout machines or equipment and perform the service and maintenance operations need to be trained in recognition of applicable hazardous energy sources in the workplace, the type and magnitude of energy found in the workplace, and the means and methods of isolating and/or controlling the energy.

- Specific procedures and limitations relating to tagout systems where they are allowed.

- Retraining of all employees to maintain proficiency or introduce new or changed control methods.

via Safety and Health Topics | Control of Hazardous Energy (Lockout/Tagout).

Prevent Golf Cart Accidents

About 13,000 golf cart-related accidents require emergency room visits each year, according to the U.S. Consumer Product Safety Commission. Types of injuries include concussions, internal injuries,bleeding in the brain, spinal cord injury, or acute respiratory compromise. Some of these injures result in death.

About 13,000 golf cart-related accidents require emergency room visits each year, according to the U.S. Consumer Product Safety Commission. Types of injuries include concussions, internal injuries,bleeding in the brain, spinal cord injury, or acute respiratory compromise. Some of these injures result in death.

The following golf cart safety tips are from the American Journal of Preventive Medicine:

- Drive at a reasonable speed, considering the weather and terrain.

- Brake slowly, especially on downhill slopes.

- Avoid sharp turns at high speeds.

- Passengers should put both feet firmly on the golf cart’s floor, keeping their arms and legs inside the cart at all times.

- Sit back in the seat so the hip restraints can help.

- Be prepared to use the handgrip to prevent a fall.

- Use seatbelts, if they’re available.

- Consider not letting let kids younger than 6 ride in golf carts and not letting kids younger than 16 drive golf carts.

What is the application of HAZCOM to an office environment?

Office workers who encounter hazardous chemicals only in isolated instances are not covered by the rule. The Occupational Safety and Health Administration (OSHA) considers most office products (such as pens, pencils, adhesive tape) to be exempt under the provisions of the rule, either as articles or as consumer products. For example with copy toner OSHA has previously stated that intermittent or occasional use of a copying machine does not result in coverage under the rule. However, if an employee handles the chemicals to service the machine, or operates it for long periods of time, then the program would have to be applied.

Office workers who encounter hazardous chemicals only in isolated instances are not covered by the rule. The Occupational Safety and Health Administration (OSHA) considers most office products (such as pens, pencils, adhesive tape) to be exempt under the provisions of the rule, either as articles or as consumer products. For example with copy toner OSHA has previously stated that intermittent or occasional use of a copying machine does not result in coverage under the rule. However, if an employee handles the chemicals to service the machine, or operates it for long periods of time, then the program would have to be applied.

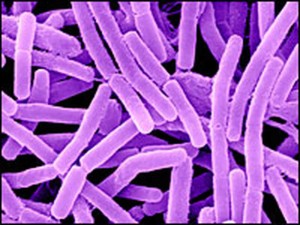

The Risk of An Insufficient Culture of Safety at CDC

Government watchdogs have warned for years about weaknesses in federal labs dealing with dangerous bugs. The CDC’s own report on the June incident details four other times that pathogens inappropriately left high-security labs since 2006, including an earlier case involving anthrax. While investigating the latest mishap, CDC Director Tom Frieden also discovered that a contagious strain of avian flu was unintentionally shipped to a lower security Department of Agriculture lab in March.

Government watchdogs have warned for years about weaknesses in federal labs dealing with dangerous bugs. The CDC’s own report on the June incident details four other times that pathogens inappropriately left high-security labs since 2006, including an earlier case involving anthrax. While investigating the latest mishap, CDC Director Tom Frieden also discovered that a contagious strain of avian flu was unintentionally shipped to a lower security Department of Agriculture lab in March.

“What we’re seeing is a pattern that we missed, and the pattern is an insufficient culture of safety,”

via CDC’s Tom Frieden Says Agency Culture Contributed to Anthrax Lapse – Businessweek.

Many Unintentional Injury Deaths are Preventable

Approximately 39 percent of the premature deaths caused by unintentional injuries in the United States every year could be prevented, according to a new study from the Centers from Disease Control and Prevention.

Approximately 39 percent of the premature deaths caused by unintentional injuries in the United States every year could be prevented, according to a new study from the Centers from Disease Control and Prevention.

The study lists unintentional injuries as the fifth leading cause of premature death (defined as death before age 80). The top four causes are heart disease, cancer, chronic lower respiratory diseases and stroke.

Unintentional injury risk factors include drug and alcohol use (including prescription drug misuse), lack of safety belt and motorcycle helmet use, exposure to occupational hazards, and unsafe homes and communities. The study suggests that if all states had the lowest observed unintentional injury death rate, 37,000 lives could be prolonged every year.

via CDC: Almost 40% of unintentional injury deaths are preventable | 2014-05-06 | Safety+Health Magazine.