Today, emerging evidence recognizes that both work-related factors and health factors beyond the workplace jointly contribute to many safety and health problems that confront today’s workers and their families. Traditionally, workplace safety and health programs have been compartmentalized. Health protection programs have focused squarely on safety, reducing worker exposures to risk factors arising in the work environment itself. And most workplace health promotion programs have focused exclusively on lifestyle factors off-the-job that place workers at risk. A growing body of science supports the effectiveness of combining these efforts through workplace interventions that integrate health protection and health promotion programs.

Today, emerging evidence recognizes that both work-related factors and health factors beyond the workplace jointly contribute to many safety and health problems that confront today’s workers and their families. Traditionally, workplace safety and health programs have been compartmentalized. Health protection programs have focused squarely on safety, reducing worker exposures to risk factors arising in the work environment itself. And most workplace health promotion programs have focused exclusively on lifestyle factors off-the-job that place workers at risk. A growing body of science supports the effectiveness of combining these efforts through workplace interventions that integrate health protection and health promotion programs.

Tag: safety

Prevent Slips, Trips and Falls at Work

Here are six guidelines to help you create a safer working environment for you and your employees.

Here are six guidelines to help you create a safer working environment for you and your employees.

1) Create Good Housekeeping Practices

Good housekeeping is critical. Safety and housekeeping go hand-in-hand. If your facility’s housekeeping habits are poor, the result may be a higher incidence of employee injuries, ever-increasing insurance costs and regulatory citations. If an organization’s facilities are noticeably clean and well organized, it is a good indication that its overall safety program is effective as well.

Proper housekeeping is a routine. It is an ongoing procedure that is simply done as a part of each worker’s daily performance. To create an effective housekeeping program, there are three simple steps to get you started

- Plan ahead– Know what needs to be done, who’s going to do it and what the particular work area should look like when you are done.

- Assign responsibilities– It may be necessary to assign a specific person or group of workers to clean up, although personal responsibility for cleaning up after himself/herself is preferred.

- Implement a program– Establish housekeeping procedures as a part of the daily routine.

2) Reduce Wet or Slippery Surfaces

Walking surfaces account for a significant portion of injuries reported by state agencies. The most frequently reported types of surfaces where these injuries occur include

- Parking lots

- Sidewalks (or lack of)

- Food preparation areas

- Shower stalls in residential dorms

- Floors in general

Traction on outdoor surfaces can change considerably when weather conditions change. Those conditions can then affect indoor surfaces as moisture is tracked in by pedestrian traffic. Traction control procedures should be constantly monitored for their effectiveness.

- Keep parking lots and sidewalks clean and in good repair condition.

- When snow and ice are present, remove or treat these elements. In some extreme cases, it may be necessary to suspend use of the area.

- Use adhesive striping material or anti-skid paint whenever possible.

Indoor control measures can help reduce the incidence of slips and falls.

- Use moisture-absorbent mats with beveled edges in entrance areas. Make sure they have backing material that will not slide on the floor.

- Display “Wet Floor” signs as needed.

- Use anti-skid adhesive tape in troublesome areas.

- Clean up spills immediately. Create a procedure for taking the appropriate action when someone causes or comes across a food or drink spill.

- Use proper area rugs or mats for food preparation areas.

3) Avoid Creating Obstacles in Aisles and Walkways

Injuries can also result in from trips caused by obstacles, clutter, materials and equipment in aisles, corridors, entranceways and stairwells. Proper housekeeping in work and traffic areas is still the most effective control measure in avoiding the proliferation of these types of hazards. This means having policies or procedures in place and allowing time for cleaning the area, especially where scrap material or waste is a by-product of the work operation.

- Keep all work areas, passageways, storerooms and service areas clean and orderly.

- Avoid stringing cords, cables or air hoses across hallways or in any designated aisle.

- In office areas, avoid leaving boxes, files or briefcases in the aisles.

- Encourage safe work practices such as closing file cabinet drawers after use and picking up loose items from the floor.

- Conduct periodic inspections for slip and trip hazards.

4) Create and Maintain Proper Lighting

Poor lighting in the workplace is associated with an increase in accidents.

- Use proper illumination in walkways, staircases, ramps, hallways, basements, construction areas and dock areas.

- Keep work areas well lit and clean.

- Upon entering a darkened room, always turn on the light first.

- Keep poorly lit walkways clear of clutter and obstructions.

- Keep areas around light switches clear and accessible.

- Repair fixtures, switches and cords immediately if they malfunction.

5) Wear Proper Shoes

The shoes we wear can play a big part in preventing falls. The slickness of the soles and the type of heels worn need to be evaluated to avoid slips, trips and falls. Shoelaces need to be tied correctly. Whenever a fall-related injury is investigated, the footwear needs to be evaluated to see if it contributed to the incident. Employees are expected to wear footwear appropriate for the duties of their work task.

6) Control Individual Behavior

This condition is the toughest to control. It is human nature to let our guard down for two seconds and be distracted by random thoughts or doing multiple activities. Being in a hurry will result in walking too fast or running which increases the chances of a slip, trip or fall. Taking shortcuts, not watching where one is going, using a cell phone, carrying materials which obstructs the vision, wearing sunglasses in low-light areas, not using designated walkways and speed are common elements in many on-the-job injuries.

It’s ultimately up to each individual to plan, stay alert and pay attention.

via 6 guidelines to prevent workplace slips, trips and falls.

Tips for Runners Staying Safe on the Roads

Take these precautions to protect yourself when you’re walking and running outside.

Take these precautions to protect yourself when you’re walking and running outside.

- Leave word. Tell somebody or leave a note at home about where you plan to go and how long you plan to be out. That way your loved ones will know to come look for you if needed.

- Identify yourself. Run with proper ID, and carry a cell phone with emergency contacts taped to its back.

- Pretend you’re invisible. Don’t assume a driver sees you. In fact, imagine that a driver can’t see you, and behave accordingly.

- Face traffic. It’s easier to see, and react to, oncoming cars. And cars will see you more clearly too.

- Make room. If traffic gets heavy, or the road narrows, be prepared to move onto the sidewalk or shoulder of the road.

- Be seen. Wear high-visibility, brightly colored clothing. When out near or after sunset, reflective materials are a must. (If you don’t own reflective clothing, a lightweight reflective vest is a great option.) And use a headlamp or handheld light so you can see where you’re going, and drivers can see you. The light should have a bright LED (drivers see blinking red as a hazard).

- Unplug your ears. Avoid using iPods or wearing headphones—you need to be able to hear approaching vehicles. If you do use headphones, run with the volume low and just one earbud in.

- Watch the hills. When they crest hills, drivers’ vision can suddenly be impaired by factors like sun glare or backdrops.

- Beware of high-risk drivers. Steer clear of potential problem areas like entrances to parking lots, bars, and restaurants, where there may be heavy traffic.

- Watch for early birds and night owls. At odd hours be extra careful. Early in the morning and very late at night, people may be overtired and not as attentive.

- Mind your manners. At a stop sign or light, wait for the driver to wave you through—then acknowledge with your own polite wave. That acknowledgement will make the driver feel more inclined to do it again for the next walker or runner. Use hand signals (as you would on a bicycle) to show which way you plan to turn.

Accident Investigation

Thousands of accidents occur throughout the United States every day. The failure of people, equipment, supplies, or surroundings to behave or react as expected causes most of them. Accident investigations determine how and why these failures occur. By using the information gained through an investigation, a similar, or perhaps more disastrous, accident may be prevented. It is important to conduct accident investigations with prevention in mind.

Thousands of accidents occur throughout the United States every day. The failure of people, equipment, supplies, or surroundings to behave or react as expected causes most of them. Accident investigations determine how and why these failures occur. By using the information gained through an investigation, a similar, or perhaps more disastrous, accident may be prevented. It is important to conduct accident investigations with prevention in mind.

Stay Safe Around Natural Gas

If you suspect a natural gas leak: Leave the area immediately and go to a safe location.

If you suspect a natural gas leak: Leave the area immediately and go to a safe location.

Do not try to locate the source of the leak.

Do not do anything that could cause a spark and ignite the gas:

- Do not use electrical devices, such as light switches, telephones, or garage door openers

- Do not use an open flame, matches or lighters

- Do not start vehicles parked in the area

Do not try to shut off any natural gas valves.

From a safe location, call your Energy Company.

Do not re-enter the building or return to the area until an Energy Company employee says it’s safe.

Signs of Natural Gas Leak

- “Rotten egg” smell

- Dead or discolored vegetation in an otherwise green area

- Dirt or dust blowing from a hole in the ground

- Bubbling in wet or flooded areas

- Blowing or hissing sound

- Flames, if a leak has ignited

- Gas in transmission pipelines does not have odorant added, so signs of a pipeline leak may include all of the above except the rotten egg odor.

Safety and Health Management Systems

What is a Safety and Health Program and where does it fit into my management system?

What is a Safety and Health Program and where does it fit into my management system?

If your team wants to reduce accidents, injuries, illnesses, and their related costs, everyone must place as much emphasis on safety and health issues as they place on other core management issues, such as production, sales, and quality control. To be most effective, safety and health must be balanced with, and incorporated into, the other core business processes.

“Safety First” may sound good, but in reality, safety should not be considered separately. Rather, it must become a basic value of your company. Change “Safety First” to “Safe production is our only standard.” This emphasizes the idea that it’s fine to produce as hard and as fast as possible, as long as it can be done safely.

Fall Protection

Why is fall protection important?

Why is fall protection important?

Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the work place to prevent employees from falling off of overhead platforms, elevated work stations or into holes in the floor and walls.

What can be done to reduce falls?

Employers must set up the work place to prevent employees from falling off of overhead platforms, elevated work stations or into holes in the floor and walls. OSHA requires that fall protection be provided at elevations of four feet in general industry workplaces, five feet in shipyards, six feet in the construction industry and eight feet in longshoring operations. In addition, OSHA requires that fall protection be provided when working over dangerous equipment and machinery, regardless of the fall distance.

To prevent employees from being injured from falls, employers must:

- Guard every floor hole into which a worker can accidentally walk (using a railing and toe-board or a floor hole cover).

- Provide a guard rail and toe-board around every elevated open sided platform, floor or runway.

- Regardless of height, if a worker can fall into or onto dangerous machines or equipment (such as a vat or acid or a conveyor belt) employers must provide guardrails and toe-boards to prevent workers from falling and getting injured.

- Other means of fall protection that may be required on certain jobs include safety and harness and line, safety nets, stair railings and hand rails.

OSHA requires employers to:

- Provide working conditions that are free of known dangers.

- Keep floors in work areas in a clean and, so far as possible, a dry condition.

- Select and provide required personal protective equipment at no cost to workers.

- Train workers about job hazards in a language that they can understand.

Carbon Monoxide

Carbon monoxide (CO) is a colorless, odorless, and toxic gas, which is predominately produced by incomplete combustion of carbon-containing materials. Incomplete combustion occurs when insufficient oxygen is used in the fuel (hydrocarbon) burning process. Consequently, more carbon monoxide, in preference to carbon dioxide, is emitted. Some examples of this are the following: vehicle exhausts, fuel burning furnaces, coal burning power plants, small gasoline engines, portable gasoline-powered generators, power washers, fire places, charcoal grills, marine engines, forklifts, propane-powered heaters, gas water heaters, and kerosene heaters.

Carbon monoxide (CO) is a colorless, odorless, and toxic gas, which is predominately produced by incomplete combustion of carbon-containing materials. Incomplete combustion occurs when insufficient oxygen is used in the fuel (hydrocarbon) burning process. Consequently, more carbon monoxide, in preference to carbon dioxide, is emitted. Some examples of this are the following: vehicle exhausts, fuel burning furnaces, coal burning power plants, small gasoline engines, portable gasoline-powered generators, power washers, fire places, charcoal grills, marine engines, forklifts, propane-powered heaters, gas water heaters, and kerosene heaters.

Exposure to carbon monoxide impedes the blood’s ability to carry oxygen to body tissues and vital organs. When carbon monoxide is inhaled, it combines with hemoglobin (an iron-protein component of red blood cells), producing carboxyhemoglobin (COHb), which greatly diminishes hemoglobin’s oxygen-carrying capacity. Hemoglobin’s binding affinity for carbon monoxide is 300 times greater than its affinity for oxygen. As a result, small amounts of carbon monoxide can dramatically reduce hemoglobin’s ability to transport oxygen. Common symptoms of carbon monoxide exposure are headache, nausea, rapid breathing, weakness, exhaustion, dizziness, and confusion. Hypoxia (severe oxygen deficiency) due to acute carbon monoxide poisoning may result in reversible neurological effects, or it may result in long-term (and possibly delayed) irreversible neurological (brain damage) or cardiological (heart damage) effects.

Carbon monoxide exposure can be dangerous during pregnancy for both the mother and the developing fetus. Please contact CDC-INFO (800-232-4636) if you have any questions regarding carbon monoxide exposure during pregnancy.

via CDC – Carbon Monoxide – NIOSH Workplace Safety and Health Topic.

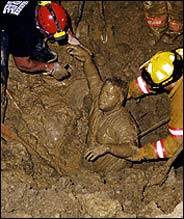

Trenching and Excavation Hazards

Cave-ins are perhaps the most feared trenching hazard. But other potentially fatal hazards exist, including asphyxiation due to lack of oxygen in a confined space, inhalation of toxic fumes, drowning, etc. Electrocution or explosions can occur when workers contact underground utilities.

Cave-ins are perhaps the most feared trenching hazard. But other potentially fatal hazards exist, including asphyxiation due to lack of oxygen in a confined space, inhalation of toxic fumes, drowning, etc. Electrocution or explosions can occur when workers contact underground utilities.

OSHA requires that workers in trenches and excavations be protected, and that safety and health programs address the variety of hazards they face. The following hazards cause the most trenching and excavation injuries:

- No Protective System

- Failure to Inspect Trench and Protective Systems

- Unsafe Spoil-Pile Placement

- Unsafe Access/Egress

Emergency Action Plan Required by OSHA

An emergency action plan (EAP) is a written document required by particular OSHA standards [29 CFR 1910.38(a)]. The purpose of an EAP is to facilitate and organize employer and employee actions during workplace emergencies. Well developed emergency plans and proper employee training (such that employees understand their roles and responsibilities within the plan) will result in fewer and less severe employee injuries and less structural damage to the facility during emergencies. A poorly prepared plan, likely will lead to a disorganized evacuation or emergency response, resulting in confusion, injury, and property damage.

An emergency action plan (EAP) is a written document required by particular OSHA standards [29 CFR 1910.38(a)]. The purpose of an EAP is to facilitate and organize employer and employee actions during workplace emergencies. Well developed emergency plans and proper employee training (such that employees understand their roles and responsibilities within the plan) will result in fewer and less severe employee injuries and less structural damage to the facility during emergencies. A poorly prepared plan, likely will lead to a disorganized evacuation or emergency response, resulting in confusion, injury, and property damage.

via Evacuation Plans and Procedures eTool | What is an Emergency Action Plan?.