It’s harvest time and with it comes unique dangers. Here is a list of a few to consider:

It’s harvest time and with it comes unique dangers. Here is a list of a few to consider:

*Regular inhalation of dust from grain bins, silos, milk vats and manure pits can cause respiratory issues such as bronchitis and other dangerous cardiac conditions. Wearing a mask over your nose and mouth can reduce risk.

*Farm vehicles such as tractors and all-terrain vehicles cause many injuries, particularly among children. Wearing a seat belt and helmet can help prevent traumatic brain injuries or even death. Children should be supervised and given only age-appropriate tasks and access to vehicles and other farm gear.

*Grain augers are one of the most dangerous pieces of farm equipment. Broken bones, electrocutions and amputations can occur if augers aren’t handled properly.

*Livestock is another common source of injury. Cattle and other farm animals can bite, kick, ram or trample someone without warning. Stay attentive and alert.

*Working long days and evenings in the field can cause dangerous levels of fatigue. Farmers may experience shortness of breath, stroke or heart attack. Try to take breaks, eat a healthy diet and get plenty of sleep.

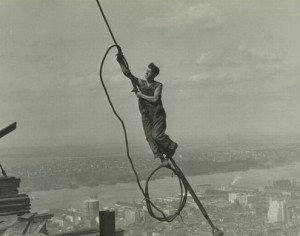

*Only enter a grain bin or gravity wagon when absolutely necessary, especially when grain is flowing. You can quickly become trapped and suffocate. If you must enter a grain bin, use a body harness and safety line secured outside the bin, and always have someone watching in case you are entrapped.

*Take special care to avoid falls, another common farm injury and the source of not only broken bones, but head injuries and other physical trauma.

*Protect eyes from debris whipped up by farm machinery.

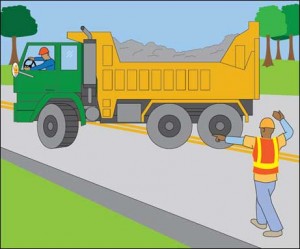

An additional tip, one that applies to non-farmers as well: Please be extra cautious driving near farm machinery on the roadways, farm vehicles need to travel slowly on occasion so give them a break.

via Mayo Clinic – Harvest-Time Danger: Mayo Clinic Expert Discusses Common Farm Injuries.