Lockout-tagout (LOTO) or lock and tag is a safety procedure which is used in industry and research settings to ensure that dangerous machines are properly shut off and not started up again prior to the completion of maintenance or servicing work. It requires that hazardous power sources be “isolated and rendered inoperative” before any repair procedure is started. “Lock and tag” works in conjunction with a lock usually locking the device or the power source with the hasp, and placing it in such a position that no hazardous power sources can be turned on. The procedure requires that a tag be affixed to the locked device indicating that it should not be turned on.

Lockout-tagout (LOTO) or lock and tag is a safety procedure which is used in industry and research settings to ensure that dangerous machines are properly shut off and not started up again prior to the completion of maintenance or servicing work. It requires that hazardous power sources be “isolated and rendered inoperative” before any repair procedure is started. “Lock and tag” works in conjunction with a lock usually locking the device or the power source with the hasp, and placing it in such a position that no hazardous power sources can be turned on. The procedure requires that a tag be affixed to the locked device indicating that it should not be turned on.

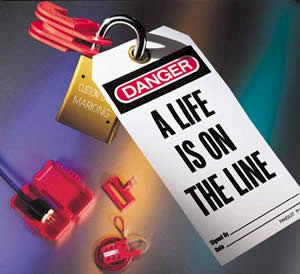

Tag: LOTO

What is Lockout/Tagout Safety Procedure?

Lockout-tagout (LOTO) or lock and tag is a safety procedure which is used in industry and research settings to ensure that dangerous machines are properly shut off and not started up again prior to the completion of maintenance or servicing work. It requires that hazardous power sources be “isolated and rendered inoperative” before any repair procedure is started. “Lock and tag” works in conjunction with a lockusually locking the device or the power source with the hasp, and placing it in such a position that no hazardous power sources can be turned on. The procedure requires that a tag be affixed to the locked device indicating that it should not be turned on.

Lockout-tagout (LOTO) or lock and tag is a safety procedure which is used in industry and research settings to ensure that dangerous machines are properly shut off and not started up again prior to the completion of maintenance or servicing work. It requires that hazardous power sources be “isolated and rendered inoperative” before any repair procedure is started. “Lock and tag” works in conjunction with a lockusually locking the device or the power source with the hasp, and placing it in such a position that no hazardous power sources can be turned on. The procedure requires that a tag be affixed to the locked device indicating that it should not be turned on.

A good Lockout/Tagout Procedure, at a minimum, should contain the following elements:

1. All maintenance personnel shall be provided with a good lock. The lock shall have the individual workers’ name and other identification on it. Each worker shall have the only key to the lock.

2. The worker shall check to be sure that no one is operating the machinery BEFORE turning -off the power. The machine operator shall be informed before the power is turned off. Sudden loss of power could cause an accident

3. Steam, air and hydraulic lines shall be bled, drained, and cleaned out. There shall be no pressure in these lines or in reservoir tanks.

4. Any mechanism under tension or pressure, such as springs, shall be released and blocked.

5. Each person who will be working on the machinery shall put a lock on the machine’s lockout device(s). Each lock shall remain on the machine until that worker’s work is complete.

6. All energy sources that could activate the machine shall be locked out (blocked/tagged).

7. The main valve or main electrical disconnect shall be tested to be sure that the power to the machine is off.

8. Electrical circuits shall be checked with proper and calibrated electrical testing equipment. An electrical failure could energize the equipment even if the switch is in the off position. Stored energy in electrical capacitors shall be safely discharged.

9. When working on machinery such as power presses and welding presses that have a ram that could fall, the ram shall be supported with safety blocks or pins. Fully interlocked safety blocks are the safest.

Control of Hazardous Energy – What is “lockout/tagout”?”

“Lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of machinery and equipment, or the release of hazardous energy during service or maintenance activities. This requires, in part, that a designated individual turns off and disconnects the machinery or equipment from its energy sources before performing service or maintenance and that the authorized employees either lock or tag the energy-isolating devices to prevent the release of hazardous energy and take steps to verify that the energy has been isolated effectively. If the potential exists for the release of hazardous stored energy or for the reaccumulation of stored energy to a hazardous level, the employer must ensure that the employees take steps to prevent injury that may result from the release of the stored energy.

“Lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of machinery and equipment, or the release of hazardous energy during service or maintenance activities. This requires, in part, that a designated individual turns off and disconnects the machinery or equipment from its energy sources before performing service or maintenance and that the authorized employees either lock or tag the energy-isolating devices to prevent the release of hazardous energy and take steps to verify that the energy has been isolated effectively. If the potential exists for the release of hazardous stored energy or for the reaccumulation of stored energy to a hazardous level, the employer must ensure that the employees take steps to prevent injury that may result from the release of the stored energy.

Lockout devices hold energy-isolation devices in a safe or”off” position. They provide protection by preventing machines or equipment from becoming energized because they are positive restraints that no one can remove without a key or other unlocking mechanism, or through extraordinary means, such as bolt cutters.

Tagout devices, by contrast, are prominent warning devices that an authorized employee fastens to energy-isolating devices to warn employees not to reenergize the machine while he or she services or maintains it. Tagout devices are easier to remove and, by themselves, provide employees with less protection than do lockout devices.