Obesity is common, serious, and costly. In 2009, about 2.4 million more adults were obese than in 2007. This epidemic has affected every part of the United States. In every state, more than 15% of adults are obese, and in nine states, over 30% of adults are obese. The medical care costs of obesity in the United States are staggering. In 2008 dollars, these costs totaled about $147 billion. More efforts are needed, and new federal initiatives are helping to change our communities into places that strongly support healthy eating and active living.

Obesity is common, serious, and costly. In 2009, about 2.4 million more adults were obese than in 2007. This epidemic has affected every part of the United States. In every state, more than 15% of adults are obese, and in nine states, over 30% of adults are obese. The medical care costs of obesity in the United States are staggering. In 2008 dollars, these costs totaled about $147 billion. More efforts are needed, and new federal initiatives are helping to change our communities into places that strongly support healthy eating and active living.

Category: Work Comp

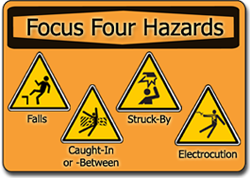

Construction’s “Fatal Four”

Out of 4,188* worker fatalities in private industry in calendar year 2011, 738 or 17.6% were in construction. The leading causes of worker deaths on construction sites were falls, followed by electrocution, struck by object, and caught-in/between. These “Fatal Four” were responsible for nearly three out of five (56%) construction worker deaths in 2011*, BLS reports. Eliminating the Fatal Four would save 419 workers’ lives in America every year.

Out of 4,188* worker fatalities in private industry in calendar year 2011, 738 or 17.6% were in construction. The leading causes of worker deaths on construction sites were falls, followed by electrocution, struck by object, and caught-in/between. These “Fatal Four” were responsible for nearly three out of five (56%) construction worker deaths in 2011*, BLS reports. Eliminating the Fatal Four would save 419 workers’ lives in America every year.

- Falls – 259 out of 738 total deaths in construction in CY 2011 (35%)

- Electrocutions – 69 (9%)

- Struck by Object – 73 (10%)

- Caught-in/between – 18 (2%)

Machine Safety is Critical

Machine safety is critical for worker safety, because machines have many ways to injure workers: Many machines have moving parts, sharp edges, and hot surfaces with the potential to cause severe workplace injuries such as crushed fingers or hands, amputations, burns, or blindness. Safeguards are essential for protecting workers from these preventable injuries. Any machine part, function, or process that might cause injury must be safeguarded. When the operation of a machine may result in a contact injury to the operator or others in the vicinity, the hazards must be eliminated or controlled.

Machine safety is critical for worker safety, because machines have many ways to injure workers: Many machines have moving parts, sharp edges, and hot surfaces with the potential to cause severe workplace injuries such as crushed fingers or hands, amputations, burns, or blindness. Safeguards are essential for protecting workers from these preventable injuries. Any machine part, function, or process that might cause injury must be safeguarded. When the operation of a machine may result in a contact injury to the operator or others in the vicinity, the hazards must be eliminated or controlled.

via CDC – Machine Safety – NIOSH Workplace Safety and Health Topic.

Nonfatal Injury and Illness in Construction

There were 3.3 million nonfatal injuries and illnesses reported across all industries in 2009, of which almost 95 per cent were injuries and just over 5 per cent were illnesses. More than 9 per cent of the nonfatal illnesses and injuries requiring days away from work were experienced by construction workers (92,540). Construction workers reported 4.3 nonfatal injuries and illnesses per 100 full-time workers.

There were 3.3 million nonfatal injuries and illnesses reported across all industries in 2009, of which almost 95 per cent were injuries and just over 5 per cent were illnesses. More than 9 per cent of the nonfatal illnesses and injuries requiring days away from work were experienced by construction workers (92,540). Construction workers reported 4.3 nonfatal injuries and illnesses per 100 full-time workers.

Falls accounted for more than one in every five of these injuries and illnesses (22%). Construction laborers experienced the seventh-highest rate of nonfatal injury and illness requiring days away from work of all occupations (382 per 10,000 full-time workers). Hispanic/Latino workers experienced nonfatal injuries and illnesses disproportionately, with almost one-fifth of cases (19%).

via CDC – Construction Safety and Health – NIOSH Workplace Safety and Health Topic.

What is Behavior-based Safety?

Behavior-based Safety is a method to use positive reinforcement to change unsafe behavior.

Behavior-based Safety is a method to use positive reinforcement to change unsafe behavior.

The system:

- Is employee-based for continuous improvement;

- Analyzes tasks and hazards to identify critical safety behaviors;

- Analyzes behavior based on job observation;

- Uses feedback about safety performance as reinforcement;

- Behavior-based Safety Principles;

- Behavior is the cause of accidents;

- Consequences motivate behavior;

- What gets measured gets done;

- Feedback is essential to improvement;

- Quality is built-in early in the process;

- Conversations change organizations;

- Behavior-based Safety and Integrated Safety Management.

via Safety Training – Safety Guidance Specialists: What is Behavior-based Safety?.

Eye Safety: Tips

1. Create a safe work environment

1. Create a safe work environment

- Minimize hazards from falling or unstable debris.

- Make sure that tools work and safety features (machine guards) are in place.

- Make sure that workers (particularly volunteers) know how to use tools properly.

- Keep bystanders out of the hazard area.

2. Evaluate safety hazards.

- Identify the primary hazards at the site.

- Identify hazards posed by nearby workers, large machinery, and falling/shifting debris.

3. Wear the proper eye and face protection.

- Select the appropriate Z87 eye protection for the hazard.

- Make sure the eye protection is in good condition.

- Make sure the eye protection fits properly and will stay in place.

4. Use good work practices.

- Caution—Brush, shake, or vacuum dust and debris from hardhats, hair, forehead, or the top of the eye protection before removing the protection.

- Do not rub eyes with dirty hands or clothing.

- Clean eyewear regularly.

- Prepare for eye injuries and first aid needs.

5. Have an eye wash or sterile solution on hand.

via CDC – Eye Safety: Checklist – NIOSH Workplace Safety and Health Topic.

Electricity – a serious workplace hazard.

Working with electricity can be dangerous. Engineers, electricians, and other professionals work with electricity directly, including working on overhead lines, cable harnesses, and circuit assemblies. Others, such as office workers and sales people, work with electricity indirectly and may also be exposed to electrical hazards.

Working with electricity can be dangerous. Engineers, electricians, and other professionals work with electricity directly, including working on overhead lines, cable harnesses, and circuit assemblies. Others, such as office workers and sales people, work with electricity indirectly and may also be exposed to electrical hazards.

Electricity has long been recognized as a serious workplace hazard. OSHA’s electrical standards are designed to protect employees exposed to dangers such as electric shock, electrocution, fires, and explosions. Electrical hazards are addressed in specific standards for the general industry, shipyard employment, and marine terminals.

Protect Young Workers this Summer

Most youth find paid employment, either during the summer or year-round, before graduating from high school. Young workers, ages 14-24, are at risk of workplace injury because of their inexperience at work and their physical, cognitive, and emotional developmental characteristics. They often hesitate to ask questions and may fail to recognize workplace dangers. OSHA has made young workers a priority within the agency and is committed to identifying ways to improve young worker safety and health. OSHA’s Young Worker Initiative addresses this group’s safety and health through a multi-pronged outreach program.

Most youth find paid employment, either during the summer or year-round, before graduating from high school. Young workers, ages 14-24, are at risk of workplace injury because of their inexperience at work and their physical, cognitive, and emotional developmental characteristics. They often hesitate to ask questions and may fail to recognize workplace dangers. OSHA has made young workers a priority within the agency and is committed to identifying ways to improve young worker safety and health. OSHA’s Young Worker Initiative addresses this group’s safety and health through a multi-pronged outreach program.

via Young Workers.

Beware – Confined Spaces

“Confined Space” refers to a space which by design has limited openings for entry and exit, unfavorable natural ventilation which could contain or produce dangerous air contaminants, and which is not intended for continuous employee occupancy. Confined spaces include but are not limited to storage tanks, compartments of ships, process vessels, pits, silos, vats, degreasers, reaction vessels, boilers, ventilation and exhaust ducts, sewers, tunnels, underground utility vaults, and pipelines. According to data collected by the U.S. Department of Labor (USDOL), Bureau of Labor Statistics (BLS) Census of Fatal Occupational Injuries (CFOI) program, fatal injuries in confined spaces fluctuated from a low of 81 in 1998 to a high of 100 in 2000 during the five-year period, averaging 92 fatalities per year.

“Confined Space” refers to a space which by design has limited openings for entry and exit, unfavorable natural ventilation which could contain or produce dangerous air contaminants, and which is not intended for continuous employee occupancy. Confined spaces include but are not limited to storage tanks, compartments of ships, process vessels, pits, silos, vats, degreasers, reaction vessels, boilers, ventilation and exhaust ducts, sewers, tunnels, underground utility vaults, and pipelines. According to data collected by the U.S. Department of Labor (USDOL), Bureau of Labor Statistics (BLS) Census of Fatal Occupational Injuries (CFOI) program, fatal injuries in confined spaces fluctuated from a low of 81 in 1998 to a high of 100 in 2000 during the five-year period, averaging 92 fatalities per year.

via CDC – Confined Spaces – NIOSH Workplace Safety and Health Topic.

Control of Hazardous Energy – What is “lockout/tagout”?”

“Lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of machinery and equipment, or the release of hazardous energy during service or maintenance activities. This requires, in part, that a designated individual turns off and disconnects the machinery or equipment from its energy sources before performing service or maintenance and that the authorized employees either lock or tag the energy-isolating devices to prevent the release of hazardous energy and take steps to verify that the energy has been isolated effectively. If the potential exists for the release of hazardous stored energy or for the reaccumulation of stored energy to a hazardous level, the employer must ensure that the employees take steps to prevent injury that may result from the release of the stored energy.

“Lockout/tagout” refers to specific practices and procedures to safeguard employees from the unexpected energization or startup of machinery and equipment, or the release of hazardous energy during service or maintenance activities. This requires, in part, that a designated individual turns off and disconnects the machinery or equipment from its energy sources before performing service or maintenance and that the authorized employees either lock or tag the energy-isolating devices to prevent the release of hazardous energy and take steps to verify that the energy has been isolated effectively. If the potential exists for the release of hazardous stored energy or for the reaccumulation of stored energy to a hazardous level, the employer must ensure that the employees take steps to prevent injury that may result from the release of the stored energy.

Lockout devices hold energy-isolation devices in a safe or”off” position. They provide protection by preventing machines or equipment from becoming energized because they are positive restraints that no one can remove without a key or other unlocking mechanism, or through extraordinary means, such as bolt cutters.

Tagout devices, by contrast, are prominent warning devices that an authorized employee fastens to energy-isolating devices to warn employees not to reenergize the machine while he or she services or maintains it. Tagout devices are easier to remove and, by themselves, provide employees with less protection than do lockout devices.